Is the Professional Speaker the Ultimate Benchmark for Audio Manufacturing Excellence?

In the highly competitive world of audio production, manufacturers—especially those specializing in loudspeakers, car audio systems, and sound reinforcement equipment—must constantly seek components that offer exceptional fidelity, robust reliability, and repeatable performance. The centerpiece of any high-quality audio solution is the Professional Speaker, a specialized driver engineered to handle demanding power levels and deliver uncompromised acoustic accuracy across its entire operational lifespan. For mechanical manufacturing firms and product service providers, understanding the critical differentiators of a Professional Speaker versus a standard consumer-grade unit is paramount to ensuring product success. This comprehensive exploration delves into the technical specifications, application-specific demands, and strategic sourcing considerations required to successfully integrate these drivers into high-value audio products.

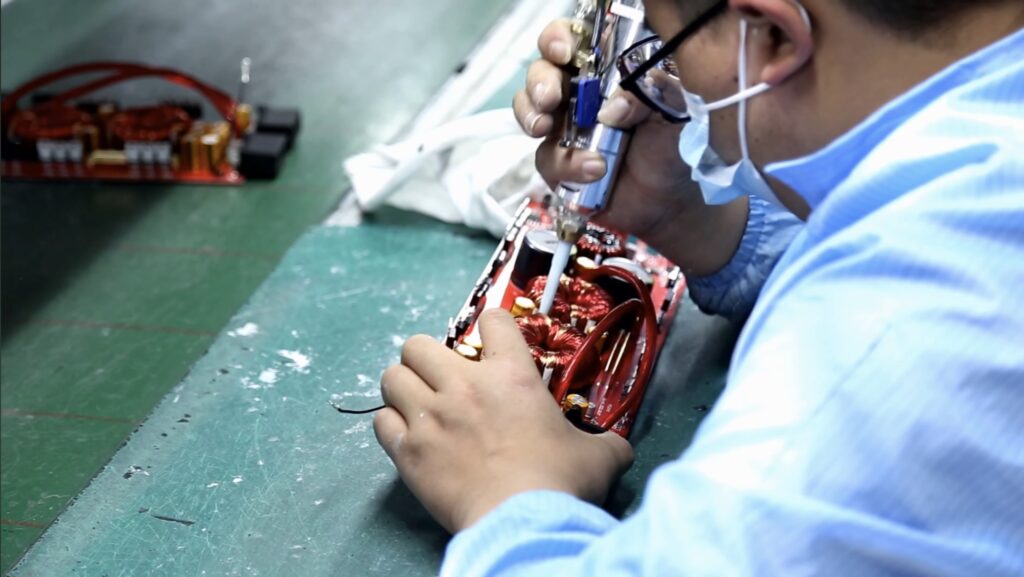

The Engineering Imperative of the Professional Speaker

A Professional Speaker is defined by its ability to perform under stress, providing consistent and accurate sound reproduction in environments ranging from recording studios to outdoor arenas. Unlike typical consumer drivers, these units are characterized by their superior power handling, low distortion at high output levels, and extended durability. This demanding performance profile necessitates a higher standard in both design and component quality, directly impacting the final product’s value proposition for the end-user.

Technical Foundations: Beyond Standard Drivers

The key technical difference lies in the robustness of the motor structure. Professional Speaker drivers typically feature larger, multi-layered voice coils capable of withstanding extreme thermal loads. The magnet assemblies are engineered for intense flux density, ensuring tight control over the diaphragm’s movement. Consequently, transient response—the speaker’s ability to react quickly to sharp changes in the audio signal—is significantly improved. Furthermore, the suspension systems (spider and surround) are designed for linearity over a far wider excursion range (Xmax) than is customary in less demanding applications. Manufacturers should rigorously evaluate the Fs (resonant frequency) and Qts (total quality factor) of these drivers, as slight variances in these parameters can severely impact the designed acoustic performance of the final enclosure.

Application Deep Dive: Tailoring the Professional Speaker for Specific Industries

The term Professional Speaker covers a broad spectrum of drivers, each tailored for highly specific acoustic and environmental challenges, particularly within the sectors of car audio, loudspeakers, and larger amplification systems. The selection process must be application-driven, focusing on how the driver’s unique characteristics align with the product’s ultimate use case.

Loudspeakers and Studio Monitors: Precision and Flatness

In high-fidelity loudspeakers and studio monitoring equipment, the primary requirement is accurate, uncolored, or “flat” frequency response. Professional Speaker drivers used here are meticulously engineered to minimize internal resonances and mass, ensuring that the sound reproduced is an exact replica of the input signal. Diaphragm materials often include lightweight, rigid composites like titanium or beryllium in compression drivers, and treated paper or exotic fibers in woofers, which achieve exceptional transient detail. For manufacturers in this niche, consistency in frequency response across the production batch is critical, as any deviation compromises the monitoring engineer’s ability to trust the sound output. Therefore, the supplier’s commitment to tight tolerance limits is an essential criterion.

The Specialized Demands of Automotive Audio

Integrating a Professional Speaker into premium car audio systems presents a different set of obstacles. The driver must perform consistently in a non-ideal acoustic environment (the car cabin) and withstand extreme conditions: fluctuating temperatures, vibration, and humidity. Here, the focus shifts to robust build quality, efficient power utilization, and compact design. Manufacturers prioritize drivers with high sensitivity (dB/W/m) to maximize acoustic output from limited amplifier power while also seeking materials that resist moisture and UV exposure. Moreover, the Professional Speaker intended for car use is often designed to fit precise factory mounting points, requiring extensive collaboration between the driver supplier and the automotive parts manufacturer to ensure seamless integration and long-term reliability within the vehicle’s complex mechanical structure.

Large-Scale Sound Reinforcement (PA) Systems

For large-scale public address (PA) and touring sound systems, the Professional Speaker must deliver enormous acoustic output with minimal thermal compression. These drivers are built like workhorses, featuring incredibly high power handling and massive magnetic structures. The cooling of the voice coil is a crucial design factor, often involving vented pole pieces or ferrofluid to dissipate heat effectively. For service product users who install and maintain these systems, the driver’s serviceability—the ease with which components like the cone and voice coil can be replaced (re-coning kits)—is a major consideration, directly affecting the total cost of ownership and maximizing system uptime during critical events.

Material Science and Longevity in Professional Speaker Design

The longevity and acoustic character of a Professional Speaker are intrinsically linked to the materials used in its construction. A successful manufacturing strategy involves understanding the trade-offs in material selection, balancing performance against manufacturing cost and product lifespan.

Voice Coils and Thermal Management

The voice coil is the most common point of failure in high-power applications. Professional Speaker coils are typically wound on high-temperature formers (such as Kapton or fiberglass) and use specialized adhesives to maintain structural integrity when temperatures soar. The material of the wire—copper or, more commonly, lighter-weight aluminum ribbon wire—also dictates thermal limits and overall driver mass. Manufacturers often demand detailed thermal breakdown specifications, ensuring the driver will not suffer permanent damage or excessive power compression during prolonged use. This commitment to thermal engineering safeguards the product’s reputation for reliability.

Cone Materials and Environmental Resilience

The diaphragm material profoundly shapes the sound. While paper pulp is common for its acoustic neutrality, Professional Speakers often utilize treated, pressed paper for superior damping or composite materials like carbon fiber or glass fiber, which offer exceptional stiffness-to-weight ratios. The surround material (the outer ring connecting the cone to the frame) is often durable, UV-resistant rubber or treated cloth, allowing for large, controlled cone excursion. For the mechanical manufacturing sector, selecting materials with inherent environmental resilience reduces the need for costly protective measures in the final product design, optimizing both performance and manufacturing simplicity.

The Manufacturer’s Strategic Guide to Sourcing the Professional Speaker

Securing the optimal Professional Speaker is a strategic undertaking that requires manufacturers to establish deep, collaborative relationships with their suppliers. The focus must be on repeatable quality and reliable supply chain management.

Quality Control and Consistency

Consistency is the ultimate mark of quality in mass production. Manufacturers must insist on suppliers that can demonstrate extremely tight manufacturing tolerances for critical parameters like Xmax, Fs, and impedance. Statistical process control (SPC) data should be utilized by the supplier to show that variances are minimal across large batches. A dedicated quality assurance (QA) protocol ensures that the Professional Speaker driver received today performs identically to the one received six months ago, guaranteeing product uniformity and reducing the risk of costly in-field failures or warranty claims. This disciplined approach is what separates premium audio products from the mass market.

Future Trends and Investment

The audio industry is continuously innovating, with new materials and manufacturing techniques constantly emerging. Strategic manufacturing partners stay ahead of the curve by investing in Professional Speaker technology that supports next-generation formats, such as drivers optimized for immersive 3D audio or high-resolution codecs. By partnering with suppliers who are aligned with these forward-looking trends, mechanical manufacturers can future-proof their product lines, ensuring that their current investment in componentry provides a pathway to adapting to the evolving demands of both consumer and professional audio markets.

❓ Frequently Asked Questions (FAQ)

Q1: What is the most critical parameter to check when sourcing a Professional Speaker for a new loudspeaker line?

A: While all parameters are important, the most critical parameter for a new design is the Fs (Resonant Frequency) combined with Qts (Total Q Factor). These Thiele-Small parameters dictate the required volume and tuning of the final speaker enclosure. Inconsistency in these measurements for a Professional Speaker batch can lead to massive discrepancies in the acoustic performance of the finished product.

Q2: How does a Professional Speaker specifically mitigate thermal compression in high-power applications?

A: A Professional Speaker addresses thermal compression through superior engineering of its voice coil and motor structure. This involves using high-temperature wire and formers, incorporating sophisticated cooling mechanisms like vented pole pieces (allowing air circulation) or internal heatsinks, and optimizing the magnetic gap to ensure efficient heat transfer away from the voice coil, thereby maintaining consistent impedance and output levels.

Q3: Can a standard speaker be replaced with a Professional Speaker in a car audio system for an immediate upgrade?

A: While a Professional Speaker offers superior potential, simply replacing a standard unit may not yield an immediate upgrade and could potentially damage the component. Professional drivers typically require more powerful amplifiers (higher RMS) and must be integrated into a properly acoustically treated environment with correct crossover settings. Using a professional driver with an underpowered factory head unit or without proper enclosure consideration will limit its performance and could even lead to failure.

I just couldn’t leave your website before suggesting that I really enjoyed the standard information a person supply for your visitors? Is gonna be again frequently in order to check up on new posts.

Just wish to say your article is as surprising. The clarity in your post is just cool and i can assume you’re an expert on this subject. Fine with your permission let me to grab your feed to keep up to date with forthcoming post. Thanks a million and please keep up the gratifying work.

Just downloaded the 5sbetapp, it seems quick. Placed a small bet on the soccer. Worth a try if you’re on the move: 5sbetapp

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me? https://www.binance.info/sk/register?ref=WKAGBF7Y

Your point of view caught my eye and was very interesting. Thanks. I have a question for you. https://www.binance.info/es/register?ref=RQUR4BEO

Howdy! I simply wish to give a huge thumbs up for the good information you’ve got here on this post. I can be coming again to your weblog for more soon.

Anyone download the bg678gamedownloadapk yet? Wondering if it’s legit. Always a bit wary about downloading APKs, you know? Has there been malware or anything found, and is it worth it? Get the APK here — at your own risk haha: bg678gamedownloadapk

You really make it appear really easy together with your presentation however I in finding this topic to be actually something that I think I’d never understand. It kind of feels too complicated and very wide for me. I am having a look ahead on your subsequent publish, I’ll try to get the cling of it!

I was studying some of your posts on this website and I conceive this site is very informative ! Continue posting.

Great post, I think website owners should acquire a lot from this web blog its really user genial.