Introduction:

In the car audio industry, OEM speakers play a crucial role in delivering excellent sound quality and user experience. With the rise of automation, speaker manufacturers have embraced modern technology to improve efficiency and ensure consistent product quality. Today, we’ll take you through the journey of a modern automated car audio production line, showcasing how it’s transforming traditional manufacturing and meeting the growing demands for car audio supplies and custom solutions.

1. What is an Automated Speaker Production Line?

An automated speaker production line integrates advanced machinery and smart systems to streamline the entire manufacturing process. From material feeding, precision assembly, to quality testing, every step is automated to reduce manual labor, speed up production, and improve product consistency.

2. Key Steps in the Automated Speaker Production Line

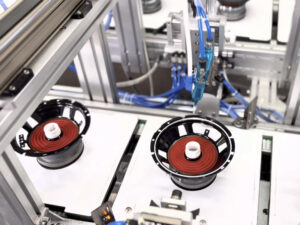

2.1 Automatic Material Feeding

- The Tyoke and Magnetic components are automatically lifted from trays onto the production line. This process eliminates the need for workers to bend over, speeds up feeding time, and improves worker efficiency.

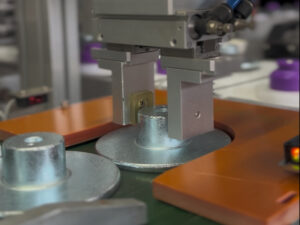

2.2 Automatic Riveting Machine

- The machine automatically rivets the clamping plate and speaker frame together.

- Benefits:

- Faster assembly speed.

- Reduces friction between frames, minimizing defects.

2.3 Automatic Removal of Positioning Gauge

- An automated system removes the positioning gauge from the speaker, reducing manual handling time and boosting production speed.

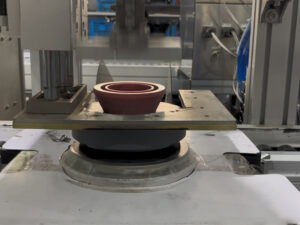

2.4 Automatic Dust Removal

- Like a vacuum, the automated dust removal system cleans multiple components during production. This reduces defects caused by dust, ensuring cleaner and higher-quality products.

2.5

- Glue application is fully automated for multiple steps, including:

- Center glue, edge glue, and dust cap glue.

- Why it matters:

Glue is critical in OEM speaker manufacturing because most parts are held together using adhesives. Automated gluing not only saves time but also ensures precision, improves aesthetics, and maintains product consistency.

The Future of Car Audio Manufacturing

The integration of automation into speaker production lines is setting a new standard for the car audio industry. Whether it’s enhancing efficiency, reducing defects, or improving product aesthetics, automated systems are paving the way for a new era of OEM speaker manufacturing.

As the industry continues to evolve, manufacturers that embrace automation will not only meet but exceed customer expectations for quality, customization, and reliability.

Want to Learn More About Automated Car Audio Manufacturing?

If you’re curious about how Audio Yong is leveraging automation to deliver high-quality car speakers and custom audio solutions, contact us today! Let us help you take your sound to the next level.